No results found

What Causes Head Gasket Failure, And How You Can Prevent It

The head gasket is one of the most important gaskets in a car and if it fails, can spell catastrophe for your beloved motor. To potentially save your car, here are the basics of this potential car killer and how to avoid trouble

What does a head gasket do?

As gaskets go, the head gasket is probably the most important within a car. Its job is to seal the combustion chambers and the coolant and oil passages between the engine block and the head. These are very important areas to keep sealed and apart from each other as the combination of unwanted coolant entering a cylinder or the oil supply is a recipe for disaster. A head gasket therefore is generally designed to never fail or need replacing, with the long bolts of the engine block squeezing it in place to a desired tolerance.

What happens when it fails?

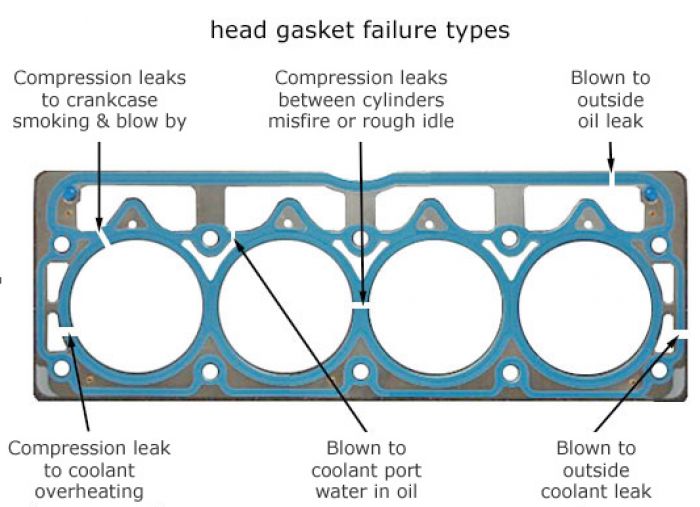

Depending on where the head gasket fails, different levels of damage can occur. If, as I experienced, your head gasket goes at a point that once separated cylinder and coolant, you can end up with a quickly overheating engine followed by steam pouring out of the exhaust and eventually a loud bang as your engine gives up the ghost.

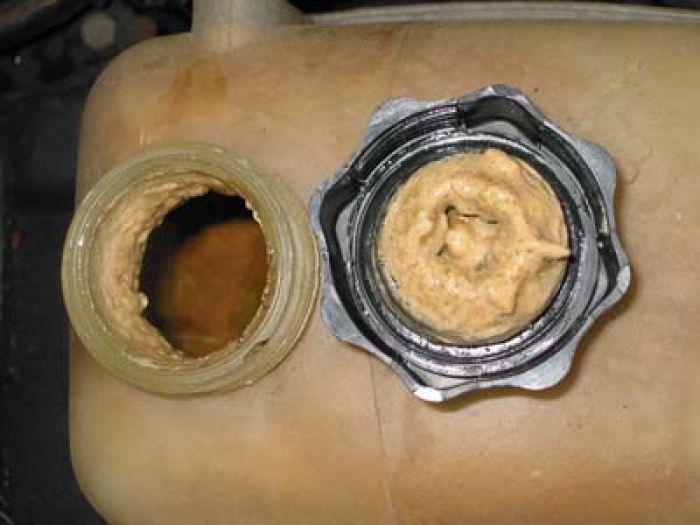

If you’re lucky, only a small failure in the gasket will occur which can be noticed through small decreases in coolant over time and yellow gunk floating around in your oil and caking the oil cap - the result of coolant entering the oil system and mixing. Temperature gauges will also sit slightly higher than standard as liquid is lost from the cooling system.

Although the gasket itself is inexpensive, the labour involved in dismantling the engine to replace it can be vast. To perform the replacement properly, the engine head will need to be extensively checked for any damage and may need to be skimmed to make sure its flatness hasn’t been compromised by overheating. Skimming is the milling of the cylinder head on a milling machine to take a very thin layer of material off the top of the head to ensure complete flatness; any small gaps will only ever lead to future failures.

What causes it to fail?

One cause of head gasket failure is pre-ignition. As fuel is combusted at unwanted times during an engine’s cycle, large pressures can occur within the cylinder head as the engine begins to work against itself. These spikes in pressure can put strain across the head gasket, causing it to fail.

Overheating is another possible cause, as the gasket is placed under conditions over and above its design criteria, resulting in warping and permanent damage. This can be purely down to coolant leaks from a corroded radiator or dodgy piping, or it could be pre-existing failures in the head gasket.

Another sub-section of overheating is the way in which your engine warms up. The gaskets within an engine are specifically designed to contain thermal properties that allow them to expand and contract as the engine warms up and cools down respectively. Hopefully as petrolheads you all know that you should wait for the engine to warm up fully before putting the foot down. I personally keep my engine speed below 3000rpm before my temperature gauge is nice and stable. But over-rev while cold and the engine and head gasket will be put under extreme thermal stresses as it expands too quickly, which can result in gasket failure as well as cracks in the head itself.

Poor gasket design can also be a car killer. A famous case of a head gasket that couldn’t cope with the thermal stresses placed upon it during its associated engine life was within the K-Series. Produced by Rover in the 1980s, the K-Series went on to feature in MGs, Lotuses and Caterhams due to its lightweight construction. The K-Series engine was revolutionary in its design, using a sand cast which had liquid aluminium poured into it. Long bolts were then used to hold together the different parts of the engine and torqued up to sandwich the K-Series together. Unfortunately, the standard gaskets were not suitable for the interaction with the aluminium engine block and thus were prone to failing as early as 40,000 miles into the engine’s life.

Strengthened gaskets can be found on the aftermarket, using different combinations of composites to add to their strength under vast changes in temperature from engine start up to peak operating conditions. Despite the hassle involved with changing the head gasket, the long term advantages of doing so could be enormous, potentially saving your car from the scrapyard.

It can be a complete lottery in terms of where failures on the gasket occur and therefore the range of potential damage is fairly extreme. From simply a small lack of coolant to a potential car killer, ‘HGF’ is not something to be taken lightly. So check your oil, check your coolant and always allow your engine to warm up before a hoon!