No results found

The Importance Of Oil Cooling And Why You Need To Take It Seriously

Oil is the life-support supply of your engine, but when it comes to cooling the oil, that's an area that's often neglected. Here's why that's a bad idea...

There are numerous viscosities of fluids coursing through a car, be it for cooling, lubrication or both. With internal combustion engines only being around 33 per cent efficient, the other 67 per cent is generally wasted through heat energy and noise, all of which has to dissipate into the surroundings in one way or another.

Oil is without doubt the most important fluid contained within a car. The sheer amount of moving parts inevitably transfers into a tonne of friction, which when spawned from metal-on-metal contact can be extremely wearing on the components. Oil is therefore used to lubricate these moving parts and in turn picks up a lot of heat.

As with the vast majority of heat energy created by an engine, it generally needs to be released to the surroundings through some form of heat exchanger. With the water-cooling system there’s the radiator and with the oil system, you use oil coolers.

Resembling miniature cross-flow heat exchangers, oil coolers can be placed in many interesting positions within a car’s body to maximise their cooling efficiency. With oil coursing through predominantly the engine block, the steering system and a turbocharger in turbocharged vehicles, oil can very quickly gain heat, especially during vigorous driving.

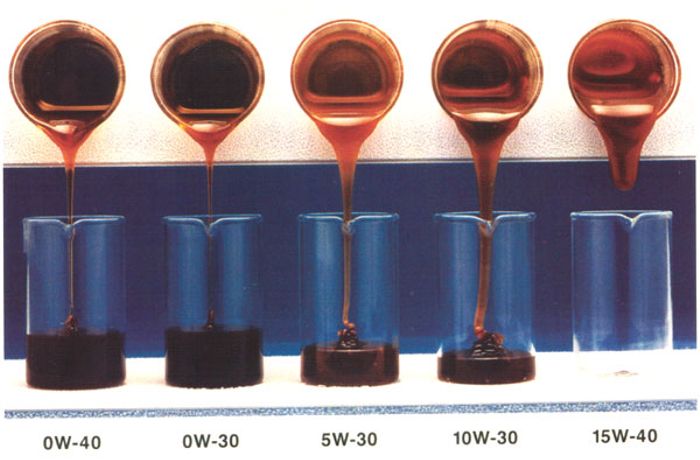

So, before the oil enters the sump or oil reservoir to be distributed around these systems, it needs to be cooled so that the oil doesn’t reach an unusable viscosity. Viscosity is a measure of how easily a fluid flows, and as oils lose and gain heat, their viscosities increase and decrease respectively. So a thick, lumpy oil has a high viscosity and a smooth, thin oil flows more easily and therefore has a lower viscosity.

Automotive oils are specially designed to sit within certain ranges of viscosity. Therefore, if too much heat is transferred to the oil, its viscosity decreases to a point where it would struggle to lubricate the required systems properly. So it becomes a balance; you want your oil to be viscous enough to cling to certain gears and other moving parts to keep them lubricated but you also want them to easily flow throughout the oil system to make it around the car’s mechanicals. And with temperature being an important factor in the change in viscosity of oil, cooling becomes an essential process.

The cooling works just like the water-cooling system, with the thermodynamics based upon the heat energy required to be dissipated to the surroundings. The oil enters the oil cooler at a high temperature, circulates through tubes that are lined with heat-releasing fins and then exits the cooler at a colder temperature, ready to recirculate and start the process all over again. Using the basic principles of thermodynamics, the size of the oil cooler needed can be calculated and can be plumbed into a car using extended oil lines to divert the fluid through the heat exchanger.

In performance cars – especially track racers and rally cars – oil cooling is extremely important due to the amount of heat transferring into the fluid from the constant flat-out driving and high-powered engines. Specific heat exchangers will be placed in areas of high air flow for maximum cooling to wick temperature away from systems like the steering, keeping the whole car at a temperature equilibrium. My favourite is the Lancia Delta Integrale Evo II which used the entire front end as an inlet for numerous coolers. Even the headlight surrounds were grilled to allow air into the engine bay and through the oil coolers desperately needed to keep the high-intensity rally car within its safe operating limits. Next time you’re at a car meet, look for gaps in the body work that are integral to a car’s design and I can guarantee that a foot or so into the duct will be a specifically positioned oil cooler.

Not all cars necessarily need specific oil cooling however; your everyday run-around will only ever need the natural cooling effects of the oil lying in the sump or coursing through other areas of lower temperatures to stay within the required viscosity limits. On the other hand, if you are planning to take your car to track days or fitting a car out for proper racing, implementing an oil cooler would be a good idea as most normal road cars aren’t designed to be thrashed for lap after lap. Engine modifications may also bring the need for an oil cooler to the front of the shopping list. As an engine produces more power, it naturally creates more heat energy which will then transfer to the oil. If this level of heat transfer is above what the original engineering was specced to cope with, then measures will need to be taken to remove this additional heat from the oil system.

In terms of positioning, a front-mounted oil cooler is possibly the simplest method. Sitting in front or beside the radiator, a small heat exchanger should be sufficient for cooling the oil in something like a Mazda MX-5 without detracting too much from the water-cooling system.

Whether we care to admit it or not, cooling is an aspect of motoring that every petrolhead should take extremely seriously. A negligence of cooling can potentially lead to catastrophic failure of the main internals of an engine, with car-killing consequences. As oil is the life-blood of an engine, keeping it within its safe operating temperature range is vitally important and something that may need to be addressed if you plan on modifying your car’s performance or taking it to the track.

Source: Car Throttle