No results found

V-TEC Vs Vanos Vs VVT-i: How Do They All Work?

Variable valve timing revolutionised IC engines, Rising to fame through JDM legends from the 90s. But how do the most well-known variants compare to each other?

Internal combustion engines have never really been that efficient from day one. Averaging at around 33 per cent thermal efficiency - the rest of the energy created by the combination of a spark, fuel and oxygen is released to the surroundings. So any way to make an IC engine produce power more efficiently has been very much sought after, with variable valve timing being possibly one of the most effective solutions.

It manages to alter valve timing (the point at which each valve opens and closes with in the engine cycle), valve duration (how long the valves stay open) and valve lift (how far the valve opens).

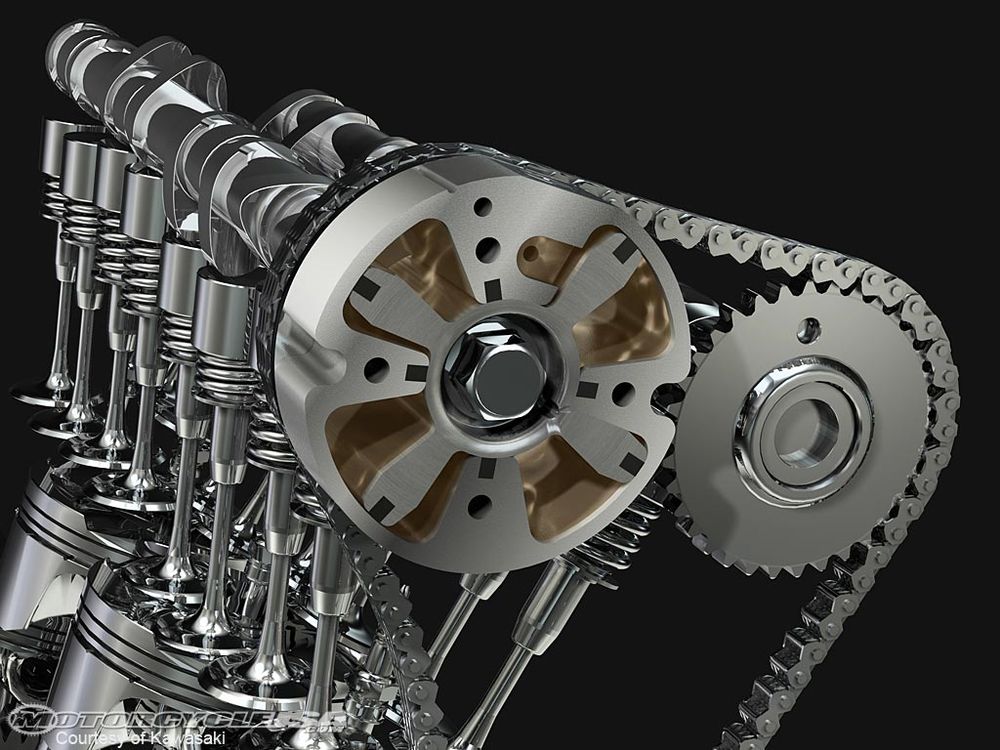

As you know, the inlet valve within an engine is opened to allow air/fuel mixture into the cylinders to then be compressed, combusted and then forced out of the cylinder through opening the exhaust valve. These valves are opened by rocker arms that are actuated by the camshaft, using lobes to perfectly time the opening and closing.

Unfortunately, standard camshafts are machined in a way that only allow for a set way for the valves to open. And that’s a problem because - for maximum efficiency - the valves need to open and close differently depending on the RPM that the engine is reciprocating at.

For high engine speeds you want a slight advance in the inlet valve opening as the sheer speed that the piston is moving can result in a lack of air being able to be sucked into the cylinder in time. Therefore, this advanced opening of the inlet valve allows slightly more oxygen to enter the cylinder to increase the efficiency of the combustion.

So instead of having to form a compromise between a camshaft for slow engine speeds and another for high engine speeds, variable valve timing was created and has been a stalwart of efficiency since its invention. There have been a few different takes on this technology, so firstly let’s take a look at the most famous of them all.

VTEC (cue the memes)

Honda’s solution came in the shape of cam changing, with two different camshaft profiles that could be picked from depending on the engine speed. VTEC (Variable Valve Timing and Lift Electronic Control) hydraulically selects between low-lift lobes for when the engine is rotating slowly and high-lift lobes for when the engine is working hard in the upper rev range. This system therefore allows for one cam profile to produce great fuel efficiency down low and another to produce a higher power output at high engine speeds, making the Honda engine extremely versatile.

The hydraulic switch is controlled by the ECU that takes in information about oil pressure, engine temperature, vehicle speed, engine temperature and engine speed. It is then programmed to pick between the two cam profiles using a solenoid which sends oil pressure from a specific valve which then forces a locking pin to finally transfer to the high-lift lobes.

This transition between cam profiles meant that Honda VTEC powerplants would produce their peak power very high in the rev range once the system had ‘kicked in’. Although it doesn’t produce a power lump akin to a turbocharger, many Honda fanboys will always have plenty to say about the last-minute surge from a VTEC engine at the top end of the engine’s capabilities.

VVT-i

Toyota’s variable valve timing system went down the route of using the cam gears to alter the relationship between the timing belt/chain and the camshaft. A smaller gear within the cam gear is able to rotate under spring loading to rotate the camshaft by an additional few degrees by delaying or advancing the interaction between the gear’s teeth and the rotating chain.

This format is known as cam phasing, as the internal gear within the cam gear can influence the phase angle of the camshaft, altering the time at which the lobes interact with their respective rocker arms. This technology was first implemented on the 2JZ-GE engine and featured on the famous A80 Supra in its 3.0-litre format.

Vanos

Vanos (or variable Nockenwellensteuerung) is BMW’s take on VVT and was first introduced on the M50 engine within the 5-series of the 90s. It also uses cam phasing but with a helical gear within the cam gear which moves towards or in the opposite direction to the camshaft, altering the lobe angle. This actuation is controlled by the DME (Digital Motor Electronics) that applies an added oil pressure to move the helical gear in and out.

As with the other systems, this helical gear will move inwards to open the valves slightly earlier, enhancing the amount of air entering the cylinder and providing an increase in power delivery. Initially, BMW introduced single Vanos which only altered the intake camshaft in defined steps within the engine RPM range. The German company then produced double Vanos which was a much more advanced system that influenced both the intake and exhaust camshafts, with adjustment also taking into account throttle position. Double VANOS was invented in time for the S50B32 engine found in Alex’s E36 M3 along with the infinitely cool Z3 M Coupe and roadster.

Nearly every car company out there has come up with its own name for a VVT system - Rover had VVC, Nissan has VVL and Ford has VCT. And there’s no wonder, considering that it is one of engineering’s win-win situations. Instead of having to pick between a low-lift and high-lift cam, automakers were suddenly able to maximise fuel efficiency and emissions along with allowing for maximum power delivery.

With the potential for pneumatic valve control on the horizon, the reign of the camshaft may be about to end in the coming years. But until that day, the power delivery of Vanos, V-TEC AND VVT-i will still have the fanboys bragging at every car meet you attend.

Source: Car Throttle